Introduction

Insulating your ground floor is an excellent way to keep your house warm, reducing draughts, heat loss and energy bills. According to energysavingtrust.org.uk, this could help you save up to £70 annually.

This blog focusses on insulating suspended timber floors, as are often found in older homes, by reusing unwanted polyester duvets. It is usually only necessary to insulate the ground floor, not upper floors, but it is also worth considering insulating any floors above unheated spaces, such as garages.

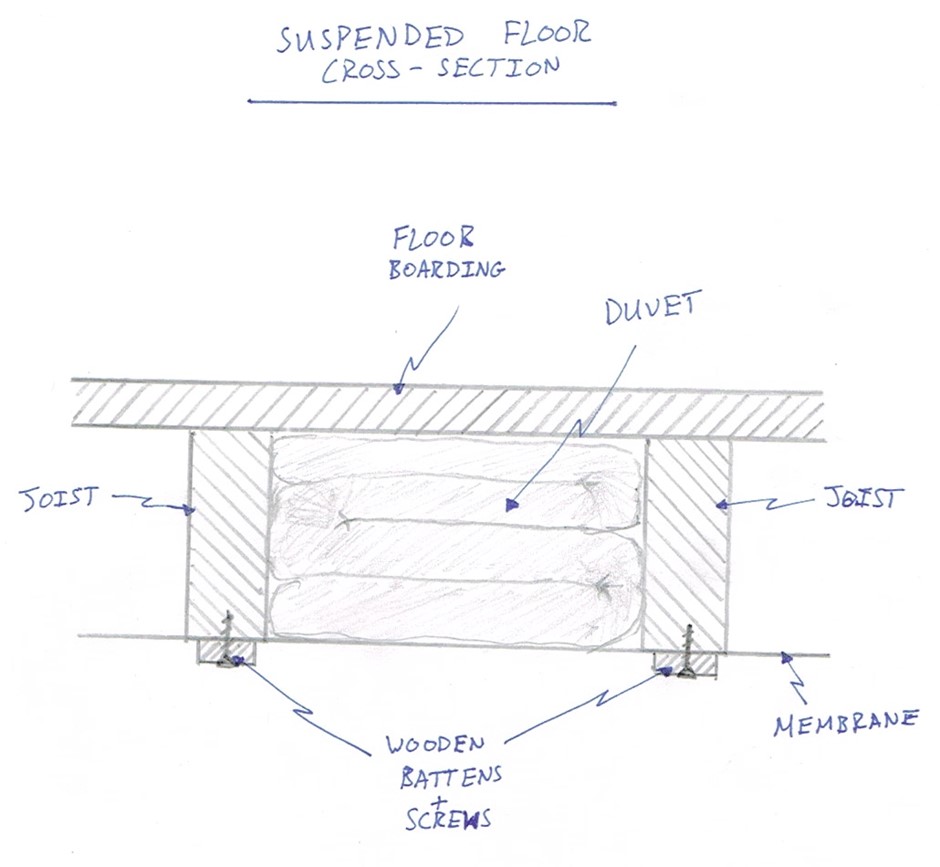

Our method is based around using these duvets to fill the gaps between the floor joists, before sealing them with a membrane to keep them as airtight and draft proof as possible. Polyester is a commonly used material for insulation, with purpose-made polyester housing insulation readily available. However, with access to a supply of discarded duvets, it is a cheap way to reuse materials, while saving unnecessary landfill waste.

Disclaimer

Fire safety. Polyester fibre wadding is highly flammable, other insulation materials such as rockwool or glasswool are not. You should content yourself that polyester insulation is appropriate for your application.

The authors are not architects, just experienced DIY people, and this blog piece is solely a description what we did in our house. It is not a recommendation. While we have discussed this method of insulation with an architect, reusing duvets is not an orthodox method approved by any building authority.

Therefore we take no responsibility whosoever for any actions that you take as a result of reading this blog piece.

Duvets as an insulation material

For this project, the duvets were sourced for no cost from local university accommodation, as new duvets are bought by students each academic year leading to massive amount of discarded duvets. A mix of double and single duvets were used, as well as a few polyester pillows for some more awkward and smaller gaps. It is important to note that only polyester duvets were used for this, not down (feather) or other materials, as these may degrade or rot over time.

The quantity of duvets required is subject to a few factors such as the joist gap and depth, in our situation we used about 1 double duvet per 2 sq metres of floor area.

Basic Layout

The basis layout we used is to fold the duvets in a Z shape into the gaps between the joists.

Caption: Cross section of suspended floor showing our method (ie. looking end on)

Caption: Photo of folded duvet stapled in place between joists

Caption: Section of floor working around central heating pipe

Fitting The Membrane

The next step is to install the membrane to the underside of the floor to prevent damp or wind from getting in the insulation. The membrane is stapled in place. Battens are then screwed along the bottom of the joists to permanently fix the membrane and its joints.

Caption: Membrane is orientated so that joints are along joists and then can be secured with battens screwed along joists.

Managing moisture

Moisture control. Normally a vapour check membrane would be put on the inside of any insulation. As water vapour usually rises, we didn’t envisage any transient moisture vapour problems with moisture descending through the floor, and therefore we didn’t use a vapour check on the inside of the insulation.

Which rooms?

Spillage of liquid on the floor could leak through the timber floor and accumulate in the insulation and cause problems such as rotting the floor. For this reason, we did not use this method of insulation under a bathroom, kitchen or any other room likely to have liquid spilled on the floor.

Interested in more?

This is summary version of our method. If you are interested in more detail see Part 2 of this blog where we go into more detail about:

- Preparing the duvets

- The confounded stapler

- Choosing and working with the membrane

- Battening

- Materials list

- Personal protective equipment we found necessary